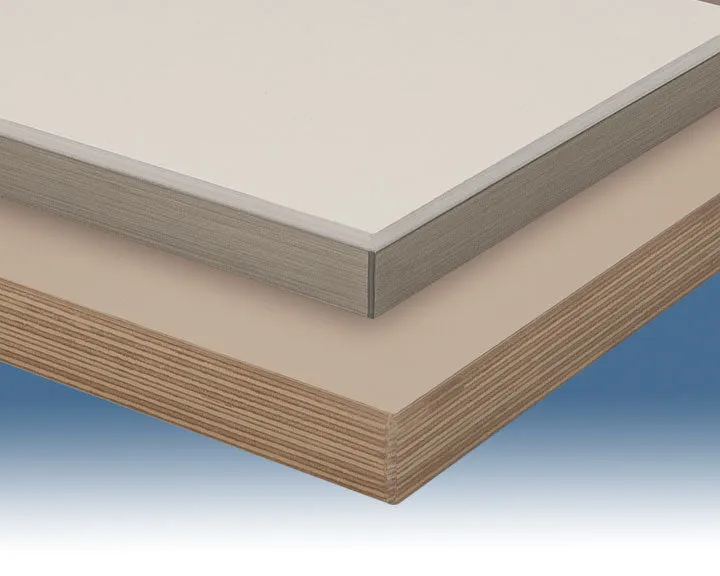

Introducing the Automatic Hot Melt Edgebander EB140 (220V) by VirutexTools, a compact yet powerful solution for professional-grade edgebanding. This machine is engineered to deliver high-quality edge finishes with precision and efficiency, making it an essential tool for woodworking professionals.

High-Performance Features

- Programmable Logic Controller (PLC): For precise control over the edgebanding process, ensuring consistent quality and performance.

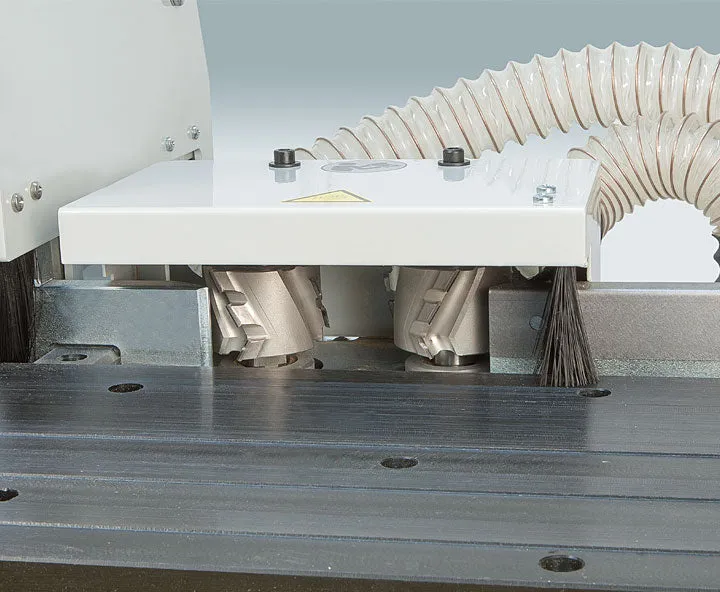

- Pre-Milling Unit: Equipped with a double head and PCD diamond inserts for perfect panel edge preparation, guaranteeing a flawless finish.

- Glue Pot Technology: Allows for the use of both low and high-temperature glues, with fast heating and a motorized gluing roller coated with polymer to minimize glue consumption.

Advanced Technology for Quality Edgebanding

- Digital Adjustments: Trimming bits and copying devices can be adjusted directly via digital meters, simplifying the setup process.

- Simultaneous Adjustments: Tape thickness, guide, and gluing roller can all be adjusted with a single digital meter for unparalleled precision.

- Automatic Tape Feeder: Features a pneumatic cutting system for seamless tape application.

- Trimming Unit: Operates at 10,000/min with adjustable copying devices for perfect edge finishing.

User-Friendly Design

- Rubber Rollers and Anti-friction Table: Ensures consistent pressure during gluing and smooth panel feeding.

- Digital Panel Thickness Adjustment: Allows for quick and easy changes to accommodate different panel sizes.

- Automatic Temperature Control: Maintains optimal working temperature and enters standby mode to prevent glue burning.